HOÁ CHẤT KHỬ KHUẨN QUANTUMTEC – VỆ SINH VÀ KHỬ KHUẨN PHÒNG SẠCH

Vệ sinh phòng sạch là quá trình làm sạch các bề mặt, thiết bị bằng các phương pháp cơ học hoặc hóa học để loại bỏ bụi bẩn và vi sinh vật.

Khử khuẩn là quá trình sử dụng các hóa chất khử khuẩn để tiêu diệt hoặc ức chế sự phát triển của vi sinh vật, bao gồm vi khuẩn, virus, và nấm.

Phòng sạch phải tuân thủ tiêu chuẩn cao về vệ sinh và vô trùng, đặc biệt là trong các khu vực sản xuất Dược phẩm và y tế, nơi đóng vai trò quan trọng trong việc đảm bảo chất lượng và an toàn sản phẩm.

1. Xây dựng SOP đảm bảo vệ sinh và khử khuẩn Phòng sạch

Xây dựng Quy trình vận hành tiêu chuẩn (SOP) là bước quan trọng để đảm bảo vệ sinh và khử khuẩn hiệu quả trong phòng sạch. Một số yếu tố cần lưu ý khi xây dựng SOP bao gồm:

- Đánh giá nguy cơ nhiễm bẩn: Cần xác định nguồn nhiễm bẩn tiềm ẩn từ không khí, con người, thiết bị để xây dựng quy trình phù hợp.

- Tần suất vệ sinh: Tùy theo khu vực và thiết bị, SOP cần quy định rõ ràng về tần suất vệ sinh hàng ngày, hàng tuần, hoặc hàng tháng.

- Lựa chọn hóa chất khử trùng: Cần chọn các loại hóa chất khử trùng phù hợp, không làm hỏng thiết bị, đồng thời đảm bảo hiệu quả tiêu diệt vi sinh vật.

- Đào tạo nhân viên: Nhân viên cần được đào tạo kỹ lưỡng về quy trình vệ sinh, sử dụng hóa chất khử khuẩn và trang thiết bị bảo hộ an toàn.

- Ghi chép và kiểm soát: Mọi hoạt động vệ sinh và khử khuẩn phải được ghi chép đầy đủ để dễ dàng truy xuất và kiểm soát chất lượng.

2. Một số hóa chất khử khuẩn thông dụng

Các hóa chất khử khuẩn phổ biến được sử dụng trong phòng sạch bao gồm:

- Sodium Hypochlorite (Javen): Là chất khử trùng mạnh mẽ, có khả năng tiêu diệt nhiều loại vi sinh vật, được sử dụng rộng rãi trong cả y tế và dược phẩm.

- Hydrogen Peroxide (H2O2): Là chất oxy hóa mạnh, giúp diệt khuẩn, virus, và nấm mốc hiệu quả mà không để lại dư lượng gây hại.

- Cồn (Ethanol, Isopropanol): Cồn thường được dùng để vệ sinh bề mặt và tay, có hiệu quả khử khuẩn nhanh chóng nhưng không tiêu diệt được bào tử vi khuẩn.

- Quaternary Ammonium Compounds (QACs): Nhóm hóa chất khử khuẩn này có tác dụng nhanh, được sử dụng rộng rãi trong các quy trình vệ sinh bề mặt phòng sạch.

3. Các yếu tố ảnh hưởng đến hiệu quả khử khuẩn

Để đạt hiệu quả khử khuẩn cao nhất, cần xem xét và kiểm soát các yếu tố sau:

- Nồng độ hóa chất: Pha chế đúng nồng độ để đảm bảo hiệu quả diệt khuẩn. Nồng độ quá thấp sẽ không đủ diệt khuẩn, còn nồng độ quá cao có thể gây hại cho thiết bị và con người.

- Thời gian tiếp xúc: Chất khử khuẩn cần đủ thời gian tiếp xúc với bề mặt để tiêu diệt hoàn toàn vi khuẩn và virus.

- Nhiệt độ và độ ẩm: Hiệu quả của các hóa chất khử khuẩn có thể bị ảnh hưởng bởi nhiệt độ và độ ẩm trong phòng sạch. Đảm bảo duy trì môi trường phù hợp cho quy trình khử khuẩn.

- Loại bề mặt: Các bề mặt nhẵn, không thấm nước thường dễ khử khuẩn hơn các bề mặt xốp hoặc gồ ghề.

- Loại vi sinh vật: Một số loại vi khuẩn hoặc virus có khả năng kháng các chất khử trùng, do đó cần lựa chọn và kết hợp nhiều phương pháp khử khuẩn khi cần.

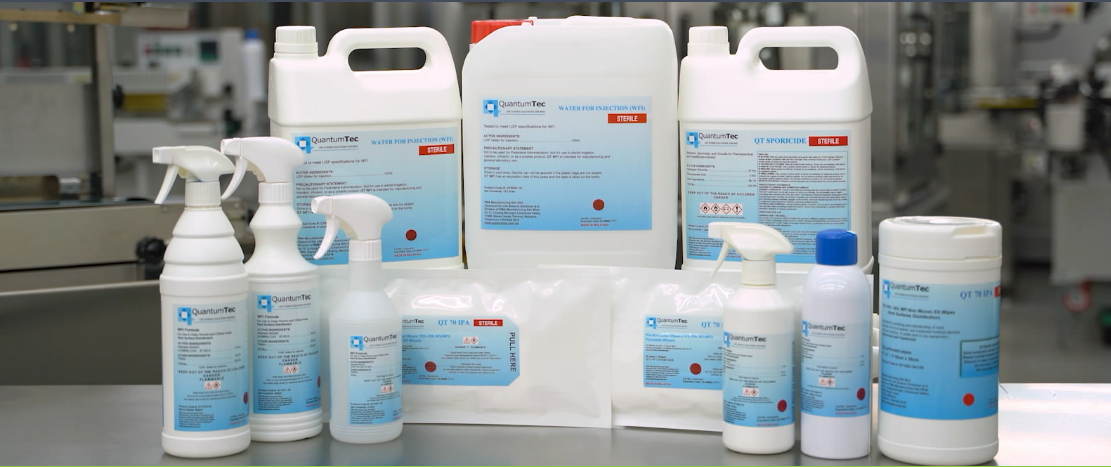

QuantumTEC thấu hiểu nhu cầu đa dạng và đặc thù của các nhà máy, vì vậy chúng tôi cung cấp nhiều lựa chọn đóng gói linh hoạt phù hợp với từng mục đích sử dụng:

- Bình xịt 476ml (Không/ Có túi trong chai)

- Bình xịt 976ml (Không/ Có túi trong chai)

- Can 1 Gallon

- Vải lau tẩm hóa chất dùng 1 lần

THƯƠNG HIỆU HOÁ CHẤT QUANTUMTEC – GIẢI PHÁP TỐI ƯU CHI PHÍ CHO NHÀ MÁY

1.Hoá chất khử khuẩn

QT 70 ISOPROPYL ALCOHOL (QT 70 IPA)

QT 70% SPECIALLY DENATURED ETHANOL (QT 70 SDA)

QT QUATERNARY AMMONIUM (QT QUAT)

QT SPORICIDE

QT PEROXY PURE

QT CHLORITE

QT CONCENTRATED DETERGENT

QT CIP

2. Hoá chất khử trùng tay

QT BAC-T-CLEAR ALCOHOL FREE HAND SANITISER

3. Khăn lau ngâm hóa chất

QT PER-SATURATED WIPES

4. Nước cất

QT WATER FOR INJECTION

![]() Xem chi tiết sản phẩm QuantumTEC tại đây

Xem chi tiết sản phẩm QuantumTEC tại đây

LIÊN HỆ NHÀ PHÂN PHỐI QUANTUMTEC ĐỘC QUYỀN TẠI VIỆT NAM

Để biết thêm thông tin chi tiết và đặt mua sản phẩm QuantumTEC , quý khách hàng vui lòng liên hệ với Sepro.

Liên hệ Sepro:

Quý khách hàng có nhu cầu đặt hàng hoặc tư vấn kỹ thuật, vui lòng liên hệ:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – Giải pháp tối ưu cho môi trường phòng sạch.

#SeproEcoClean #QuantumTec #HóaChấtKhửTrùng #PhòngSạch #Giải pháp phòng sạch #H2O2 (3%,6%) #Hydrogen Peroxide #Quat #Sporicide #IPA 70 #CIP #SDA #Detergent #WFI

Các sản phẩm chính:

Hóa chất khử trùng QuantumTec – Thương hiệu từ Mỹ, sản xuất tại Malaysia, với chi phí cạnh tranh và thời gian giao hàng nhanh chóng. Sepro hiện là đại lý độc quyền phân phối các dòng sản phẩm của QuantumTec tại Việt Nam.

Vật tư phòng sạch:

- Vải lau phòng sạch (Polyester, CP), Tăm bông, cây lau Phòng sạch, Thảm dính bụi.

- Quần áo, găng tay Phòng sạch và Kính chống đọng sương.

Dịch vụ:

- Giặt quần áo, giày và găng tay Phòng sạch đáp ứng tiêu chuẩn ISO 14644-1, FED 209E và GMP (EU, WHO)

- Gia công: Kệ, xe đẩy, thiết bị lọc và các sản phẩm phụ trợ khác dùng trong môi trường Phòng sạch

Sepro cam kết cung cấp giải pháp toàn diện cho môi trường Phòng sạch, đáp ứng tiêu chuẩn GMP – ISO khắt khe trong ngành Dược phẩm, y tế.

Tham khảo thêm bài viết trên FanPage

>>> Lựa chọn Hydrogen peroxide 30% thịnh hành tại Việt Nam