ISO STANDARD CLEANROOM COVERALL

In industries that require a sterile working environment such as electronics, medical, pharmaceutical and microchip manufacturing, ISO-certified Cleanroom Coverall becomes an important factor to protect products from contamination and ensure worker safety. So, what is cleanroom clothing and why is it necessary to meet ISO standards? Let’s find out through this article!

1. What are Cleanroom Coverall?

Cleanroom coverall are specialized attire designed to minimize the risk of releasing dust particles, bacteria, and contaminants from the human body into the work environment. These garments are primarily used in industries such as:

- Semiconductor and microchip manufacturing

- Healthcare and pharmaceuticals

- Biotechnology

- Optical equipment and precision machinery production

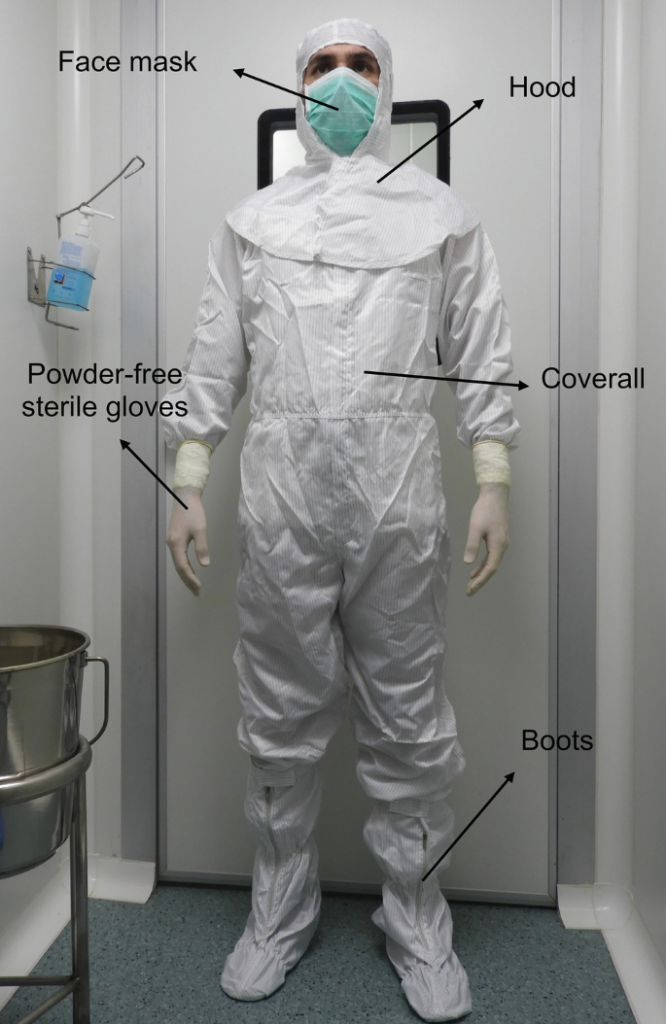

Cleanroom coveral typically include a full-body suit, cap, mask, gloves, and protective footwear. These items play a vital role in maintaining a standard-compliant cleanroom environment

2. Why must Cleanroom Coverall meet ISO Standards?

ISO standards, particularly ISO 14644, are established to ensure that cleanrooms maintain a certain level of particle control. ISO-compliant cleanroom garments must meet strict requirements for:

- Anti-static properties: Prevents static charge buildup, avoiding damage to sensitive products such as electronic components.

- Particle containment: Minimizes the risk of particles, bacteria, and microorganisms being released from the human body into the cleanroom environment.

- Safe materials: Made from special fabrics that do not generate dust and are easy to clean and sterilize.

3. ISO-Compliant Cleanroom Coverall Manufacturing Process

To produce ISO-compliant cleanroom coverall, manufacturers must adhere to strict procedures, from material selection to production and quality control:

- Materials: Fabrics used in cleanroom garments are typically polyester or other materials with antibacterial and anti-static properties.

- Design: Garments must be fully enclosed, with zippers and dust-blocking flaps to minimize the release of particles from the wearer.

- Quality Control: Products are inspected and tested according to ISO standards before being approved for use. This process ensures that the garments effectively contain particles, do not release contaminants during movement, and resist other sources of contamination.

4. ISO Standards related to Cleanroom Coverall

When it comes to cleanroom coverall, several key ISO standards must be met:

- ISO 14644: This standard regulates cleanroom environments based on airborne particle counts. Cleanroom coverall must meet requirements for containing particle release within the space.

- ISO 374: This standard provides protection against chemicals and microorganisms. In workplaces with hazardous chemicals, cleanroom coverall must be impermeable and chemically non-reactive.

- ISO 13982: This standard specifies protective clothing requirements against solid particles. It helps protect workers in production environments at risk from small hazardous particles.

5. Benefits of Using ISO-Compliant Cleanroom coverall

Using ISO-compliant cleanroom coverall offers numerous advantages for both businesses and employees:

- Product Protection: In high-tech manufacturing industries, even a single dust particle can cause significant damage to products. Cleanroom coverall help maintain a sterile production environment, protecting products from contamination.

- Employee Health Protection: ISO-standard coverall not only safeguard products but also ensure the safety of workers by reducing the risk of exposure to bacteria, viruses, and other harmful agents.

- Enhancing Business Reputation: Utilizing internationally certified protective products demonstrates a company’s commitment to quality and safety, thereby enhancing its reputation and building trust with partners and customers.

6. Instructions for using and Maintaining Cleanroom coverall

To ensure long-lasting protective effectiveness, cleanroom coverall must be used and maintained properly:

- Usage: Employees should follow the correct procedures when wearing the garments to avoid releasing dust particles from their bodies into the environment. Change clothes after each shift or when the garments become soiled or damaged.

- Maintenance: Cleanroom coverall must be laundered using special methods, avoiding harsh detergents that can damage the fabric. After washing, they should be stored in specialized bags to prevent recontamination.

7. Where to Choose ISO-Compliant Cleanroom Coverall?

Currently, there are many reputable suppliers specializing in ISO-standard cleanroom coverall. SEPRO is a reliable choice in the cleanroom field. SEPRO’s products are made from high-quality materials that enhance durability and anti-static properties, making them suitable for stringent environments. They can be customized to meet specific requirements regardless of quantity. SEPRO coverall fully comply with ISO standards.

Contact Sepro:

If you need to order or have technical advice, please contact:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – The optimal solution for clean room environments.

#SeproEcoClean #QuantumTec #Disinfectant Chemicals #Clean Room #Clean Room Solutions #Clearoomcoverall

Main products:

QuantumTec disinfectant chemicals – Brand from the US, manufactured in Malaysia, with competitive costs and fast delivery time. Sepro is currently the exclusive distributor of QuantumTec products in Vietnam.

Cleanroom supplies:

- Cleanroom Wipers (Polyester, CP), Cleanroom swabs, Mopping System, Sticky Mats.

- Cleanroom coverall, gloves and Anti-fog glasses.

Services:

- Washing of cleanroom wipers, shoes and gloves meeting ISO 14644-1, FED 209E and GMP (EU, WHO) standards

- Processing: Shelves, trolleys, filters and other auxiliary products used in cleanroom environments

Sepro is committed to providing comprehensive solutions for Cleanroom environments, meeting strict GMP – ISO standards in the pharmaceutical and medical industries.

See more articles on the FanPage

>>>Isopropyl Alcohol 70% Wipes: Key Benefits and Practical Applications