WHAT ARE CLEANROOM SWABS? CLASSIFICATION AND APPLICATION OF CLEANROOM SWAB

In the modern industrial age, the requirements for hygiene and safety in production are becoming more stringent, especially in the fields of electronics, pharmaceuticals and medical.

Cleanroom Swabs have been developed as an ideal tool for cleaning and contamination control.

This article will provide an in-depth look at Cleanroom Swabs, their classification and applications in important fields.

1. Introduce

Cleanroom Swabs are cotton swabs manufactured for use in cleanrooms – environments where humidity, temperature, and particle size are strictly controlled.

They are often used to clean and treat small, narrow surfaces that other cleaning tools such as cleanroom wipers cannot reach.

Cleanroom Swabs come in many different sizes, shapes, and materials, but they are all made from non-linting materials such as polyester, foam, or nylon.

Some are also anti-static, which helps prevent the buildup of static electricity, which can damage sensitive electronic components.

2. What types of Cleanroom Swabs are used in Cleanroom?

Below is a table suitable for cleanrooms:

| Material | Characteristic |

Application |

| Foam Swab | Bọt polyurethane. Thấm hút cao, đàn hồi tốt, bền và vẫn có tạo sợi. | Cleaning of sensitive surfaces, with solvents. Cleanroom: ISO 5–7. |

| Polyester Swab | Polyester. Low dust and fiber, durable, absorbent and compatible with many chemicals. | Cleaning of electronic and optical components. Clean room: ISO 3–5. |

| Microfiber Swab | Polyester and polyamide. Good particle retention, non-fibrous, highly absorbent, chemically resistant and non-abrasive. | Cleaning of optics, lenses, delicate components. Cleanroom: ISO 3–6. |

| Cotton Swab | Natural cellulose fiber. Highly absorbent but leaves fibers behind. | General cleaning in less demanding environments. Cleanroom: ISO 7–8. |

| ESD-Safe Swab | Foam, polyester or anti-static cotton. Good absorbency, anti-static. | Manufacturing of electronic and semiconductor equipment. Clean room: ISO 3–7. |

| Gel Swab | Sensitive rubber or gel tip. Flexible, pliable, resilient and non-scratching. | Cleaning camera sensors, optical surfaces, hard drives, and hard-to-reach areas. Cleanroom: ISO 3–7. |

| Cotton swab tip design and size | Big head | Suitable for cleaning large surfaces. |

| Small and pointed head | For use in hard to reach or narrow spaces. | |

| Flat head | Helps clean flat surfaces or corners. | |

| Length and handle material | Length |

=> suitable for different work requirements. |

| Rolling material | · Polypropylene (PP)

· Aluminum · Wood · Stainless steel |

3. Advantages and disadvantages of each type

To help you easily choose the right product, here are the advantages and disadvantages of each popular type.

| Advantage | Disadvantage | |

| Foam Swab | – Good dust and liquid retention

– Suitable for sensitive surfaces |

– Suitable for clean room use

– May generate dust and fibres |

| Polyester Swab | – Low dust and fiber generation

– High durability – Compatible with many chemicals |

– Absorbency is lower than foam |

| Microfiber Swab | – Holds particles and absorbs well

– Does not form fibers – Smooth, scratch-free- Holds particles and absorbs well – Does not form fibers – Smooth, scratch-free |

– Price is higher than some other types of cotton swabs |

| Cotton Swab | – Good absorbency

– Cheap price |

– Creates fibers and dust

– Low durability – Not suitable for high level cleanrooms |

| ESD-Safe Swab | – Low granulation, good absorption

– Antistatic |

– Higher price than cotton |

| Gel Swab | – Scratch-free

– Flexible, resilient – Holds and picks up dust and fibers well |

– Easily deformed under strong force |

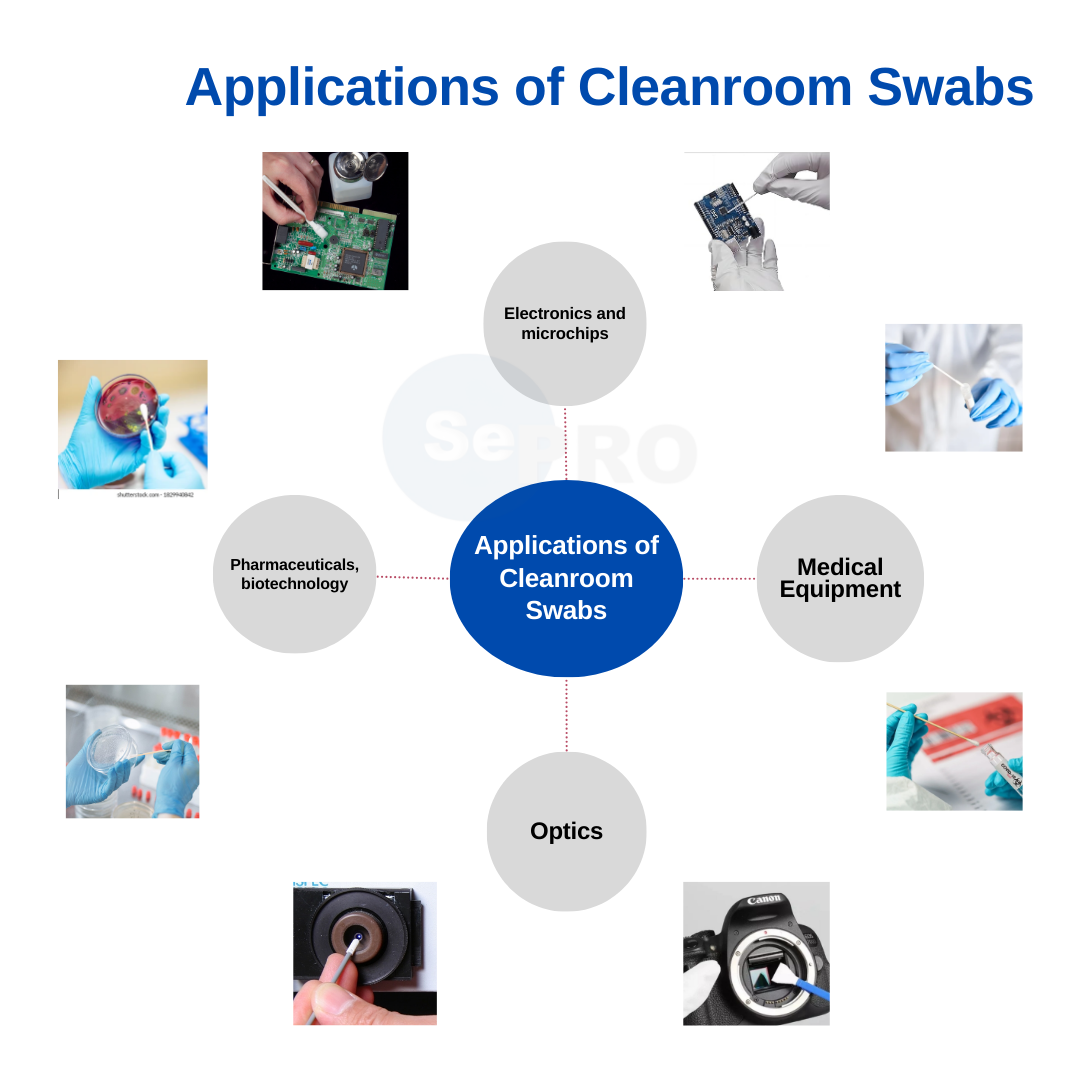

4. Applications in industries

Widely used in many industries requiring strict control of dust, micro-particles, and static electricity.

Key applications include:

- Electronics and microchip manufacturing: Used for cleaning small electronic components, testing and maintaining the surface of microchips and sensors.

- Pharmaceutical and biotechnology industry: Used for sampling, quality control and cleaning laboratory equipment without contaminating the sample.

- Medical industry: Helps prevent infection and ensure the accuracy of processes.

- Optical industry: Helps clean these surfaces without causing damage to sensitive optical equipment such as camera lenses and spectrometers that need to be protected from dirt.

Conclude

Cleanroom swabs are an indispensable tool in environments that require high levels of cleanliness. Using Cleanroom swabs properly will ensure a safe and quality working environment.

Contact to buy products

If you are looking for high-quality Cleanroom Swabs or need advice on the right type of swab for your working environment, do not hesitate to contact us.

We specialize in providing standard cleanroom swabs, suitable for many industries such as medical, pharmaceutical, electronics and many other fields.

Contact Sepro:

If you need to order or have technical advice, please contact:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – The optimal solution for clean room environments.

#SeproEcoClean #QuantumTec #Disinfectant Chemicals #Clean Room #Clean Room Solutions #H2O2 3% #Peroxy Pure #Hydrogen Peroxide

Main products:

QuantumTec disinfectant chemicals – Brand from the US, manufactured in Malaysia, with competitive costs and fast delivery time. Sepro is currently the exclusive distributor of QuantumTec products in Vietnam.

Cleanroom supplies:

- Cleanroom Wipers (Polyester, CP), Cleanroom swabs, Mopping System, Sticky Mats.

- Cleanroom coverall, gloves and Anti-fog glasses.

Services:

- Washing of cleanroom wipers, shoes and gloves meeting ISO 14644-1, FED 209E and GMP (EU, WHO) standards

- Processing: Shelves, trolleys, filters and other auxiliary products used in cleanroom environments

Sepro is committed to providing comprehensive solutions for Cleanroom environments, meeting strict GMP – ISO standards in the pharmaceutical and medical industries.

See more articles on the FanPage

>>> Khăn Lau Phòng Sạch: Giải Pháp Vệ Sinh Tối Ưu Cho Môi Trường Kiểm Soát