CLEANROOM LAUNDRY SERVICE

In industries such as pharmaceuticals, medical and electronics, the use of cleanroom coveralls is a key factor to ensure product quality and production processes.

Cleanroom laundry service were born not only to control dust, eliminate static electricity, but also save costs and extend the life of the garment.

Let’s find out why cleanroom laundry service are needed, the laundry process and the strict control standards that cleanroom laundry service meet.

1. Why do we need cleanroom laundry service?

Dust control: The washing process controls the quantity and size of dust particles in the clothes.

Some cleanroom standards such as: ISO 14644-1, FED 209E or GMP are used to evaluate and maintain the cleanroom environment.

- The washing process is performed in a Class 1000 Cleanroom (FED STD 209E): Maximum 1,000 particles (≥ 0.5 microns), 100 particles (≥ 1 micron), and 10 particles (≥ 5 microns) per cubic foot of air.

Cost savings: Businesses do not need to invest in separate machinery and human resources for cleanroom laundry, which helps optimize operating costs.

Increase product life: With temperature and humidity control processes and the use of mild chemicals, cleanroom laundry services help maintain fabric durability and quality.

Antistatic: Laundry services use specialized chemicals and technology to eliminate static electricity, such as antistatic chambers and packaging processes that control temperature and humidity.

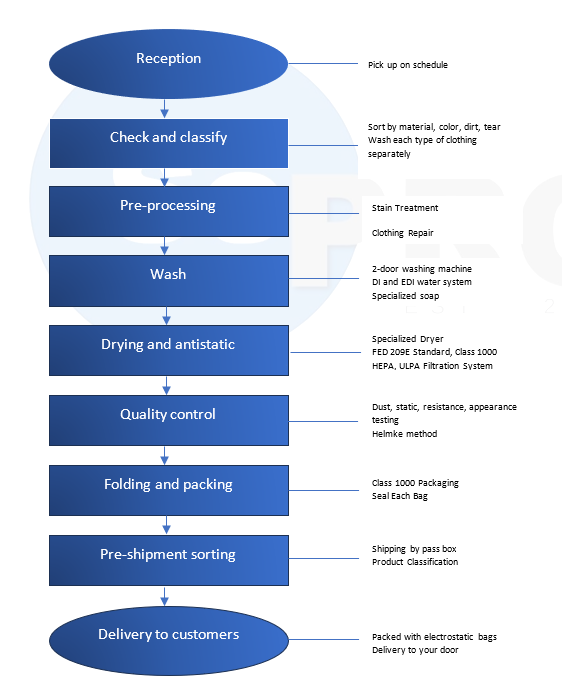

2. Sepro’s cleanroom laundry process

Step 1: Receive goods

- Pick up goods at customer’s factory according to pre-arranged schedule, ensuring on-time delivery and safe transportation process.

Step 2: Check and classify cleanroom coverall

- Sort by factors such as: Fabric material and color; Degree of soiling or tearing; Small or difficult-to-wash stains

- Separate washing for each type of clothing such as clothes, shoes, gloves and notify customers if the product cannot be processed or needs to be replaced.

Step 3: Preprocessing

- Treat heavy stains in the pre-treatment area with specialized chemicals to remove stubborn stains. At the same time, repair and maintenance, including changing locks, patching and gluing to ensure the product is in the best condition.

Step 4: Wash with a specialized washing machine

- Use a 2-door washing machine to avoid cross-contamination.

- Use DI (Deionized) and EDI (Electro Deionized) water systems with a capacity of > 20m³/h, conductivity of 18.5 mΩ. Specialized soap is designed specifically for cleanroom items to avoid chemical residues on fabrics.

Step 5: Drying and antistatic

- Specialized dryer helps dry clothes without wrinkles, increases durability and maintains fabric quality. The washing environment meets FED 209E, Class 1000 standards, equipped with HEPA and ULPA filter systems that filter dust down to 0.3 micron.

Step 6: Quality check

- Take samples to test for dust, static electricity, surface resistance and appearance. Use the Helmke method to measure the quantity and size of dust particles to test the safety and usability of the garment.

Step 7: Fold and packing

- Garments are packed in a Class 1000 clean room and each bag is sealed with a heat sealer to avoid dust contamination during transportation.

Step 8: Sorting before delivery

- Use pass box for outbound transportation, ensure no contamination from the outside environment and classify products according to customer requirements.

Step 9: Deliver to customer

- Pack products in electrostatic bags and deliver to destination according to arranged schedule, ensuring progress and customer requirements.

3. Quality Control Standards Before Delivery

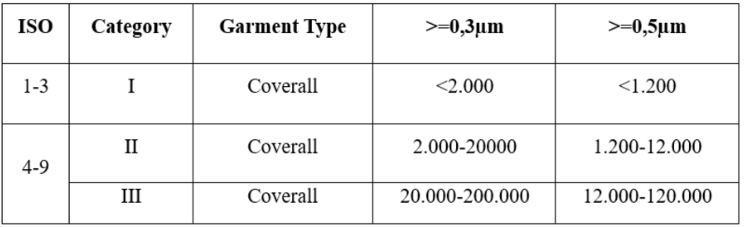

The Helmke Drum is a method for determining the ability of cleanroom garments to release particles from surfaces. It measures the quantity and size of particles released, ensuring that the garment meets the stringent requirements for particle release, according to IEST-RP-C003.4. The Helmke Drum method divides products into three levels based on the amount of particles released for each particle size.

Conclusion

Cleanroom laundry service is a solution to ensure the safety of clothing in the production environment.

The laundry process helps control dust, eliminate static electricity and maintain fabric durability, helping businesses optimize costs.

The washed clothes meet strict standards such as ISO 14644-1, FED 209E or GMP along with a strict Helmke inspection process.

SEPRO’s cleanroom laundry service brings peace of mind to customers, helping you maintain a clean and efficient working environment.

Contact Sepro:

If you need to order or have technical advice, please contact:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – The optimal solution for clean room environments.

#SeproEcoClean #QuantumTec #Disinfectant Chemicals #Clean Room #Clean Room Solutions #H2O2 3% #Peroxy Pure #Hydrogen Peroxide

Main products:

QuantumTec disinfectant chemicals – Brand from the US, manufactured in Malaysia, with competitive costs and fast delivery time. Sepro is currently the exclusive distributor of QuantumTec products in Vietnam.

Cleanroom supplies:

- Cleanroom Wipers (Polyester, CP), Cleanroom swabs, Mopping System, Sticky Mats.

- Cleanroom coverall, gloves and Anti-fog glasses.

Services:

- Washing of cleanroom wipers, shoes and gloves meeting ISO 14644-1, FED 209E and GMP (EU, WHO) standards

- Processing: Shelves, trolleys, filters and other auxiliary products used in cleanroom environments

Sepro is committed to providing comprehensive solutions for Cleanroom environments, meeting strict GMP – ISO standards in the pharmaceutical and medical industries.

See more articles on the FanPage