KIỂM SOÁT VI SINH TẠI PHÒNG SẠCH

Phòng sạch là môi trường được kiểm soát chặt chẽ để hạn chế tối đa sự hiện diện của vi sinh vật và hạt bụi trong không khí.

Kiểm soát vi sinh, hạt bụi tại phòng sạch là yếu tố quan trọng không chỉ trong ngành dược phẩm mà còn trong sản xuất thực phẩm, điện tử, và y tế.

Bài viết này sẽ giúp bạn hiểu rõ hơn về vai trò và phương pháp kiểm soát vi sinh tại phòng sạch một cách hiệu quả.

1.Tại sao cần kiểm soát vi sinh tại phòng sạch

- Đảm bảo chất lượng sản phẩm: Nhiễm vi sinh có thể làm biến đổi thành phần, giảm hiệu quả hoặc gây hỏng hóc sản phẩm.

- Tuân thủ quy định pháp luật: Các tiêu chuẩn như GMP (Good Manufacturing Practices), ISO 14644 hoặc FDA yêu cầu kiểm soát vi sinh trong phòng sạch để đảm bảo an toàn và chất lượng sản phẩm.

- Ngăn ngừa nhiễm chéo: Nhiễm chéo nếu không kiểm soát tốt sẽ ảnh hưởng nghiêm trọng đến hiệu quả sản xuất và uy tín doanh nghiệp.

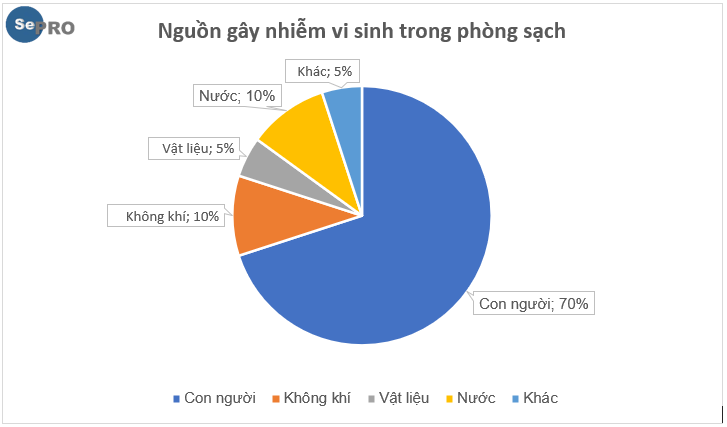

2. Các nguồn gây nhiễm vi sinh trong phòng sạch

- Con người: Nhân viên có thể mang vi sinh vật qua hơi thở, da, hoặc quần áo.

- Không khí: Vi sinh vật trong không khí, đặc biệt là ở các khu vực không được kiểm soát, dễ gây nhiễm chéo.

- Vật liệu, nước và thiết bị: Vật liệu, nguồn nước hoặc thiết bị sản xuất và vật dụng vệ sinh không đạt chuẩn là nguồn lây nhiễm.

- Môi trường sản xuất: Những khu vực không được vệ sinh thường xuyên là môi trường lý tưởng cho vi sinh vật phát triển.

3. Giải pháp kiểm soát vi sinh

3.1 Thiết kế và bảo trì

- Phòng sạch đạt chuẩn: Đảm bảo đạt chuẩn ISO 14644-1, GMP và FED 209E để kiểm soát hạt bụi tùy theo yêu cầu sản phẩm.

- Hệ thống HVAC: Kiểm soát áp suất, nhiệt độ, và độ ẩm để giảm thiểu nguy cơ phát triển vi sinh vật, giúp kiểm soát vi sinh.

- Vật liệu bề mặt: Sử dụng vật liệu chống thấm, dễ vệ sinh như thép không gỉ hoặc nhựa đặc biệt chuyên cho phòng sạch

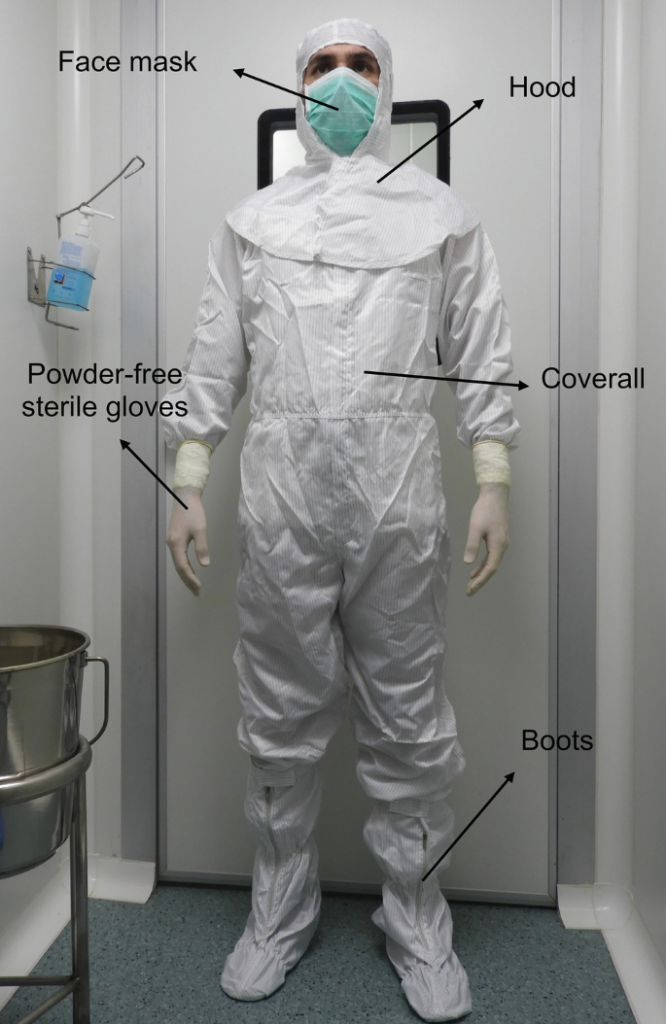

3.2 Kiểm soát con người

- Đào tạo: Nhân viên cần được huấn luyện về các quy trình làm việc, sử dụng và vệ sinh phòng sạch.

- Trang bị bảo hộ: Sử dụng quần áo bảo hộ phòng sạch, mũ trùm đầu, kính, khẩu trang, găng tay, và giày đạt chuẩn.

3.3 Vệ sinh và khử trùng

- Quy trình làm sạch: Thực hiện quy trình làm sạch hàng ngày, hàng tuần và định kỳ.

- Hóa chất khử trùng: Sử dụng các sản phẩm khử trùng có khả năng tiêu diệt cả vi khuẩn, nấm và bào tử.

3.4 Giám sát và kiểm tra

- Kiểm tra định kỳ: Lấy mẫu và phân tích vi sinh từ không khí, bề mặt, và nước sử dụng trong sản xuất.

- Công nghệ mới: Áp dụng các thiết bị tự động và cảm biến để giám sát liên tục các chỉ số vi sinh.

4. Kết luận

Kiểm soát vi sinh tại phòng sạch không chỉ là yêu cầu bắt buộc trong sản xuất mà còn là chìa khóa để đảm bảo chất lượng và uy tín lâu dài. Đầu tư vào công nghệ và giải pháp kiểm soát vi sinh sẽ giúp doanh nghiệp tối ưu hóa quy trình và tăng cường khả năng cạnh tranh trên thị trường.

Liên hệ Sepro:

Quý khách hàng có nhu cầu đặt hàng hoặc tư vấn kỹ thuật, vui lòng liên hệ:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – Giải pháp tối ưu cho môi trường phòng sạch.

#SeproEcoClean #QuantumTec #HóaChấtKhửTrùng #PhòngSạch #Giải pháp phòng sạch #STICKYMAT #Thamdinhbui

Các sản phẩm chính:

Hóa chất khử trùng QuantumTec – Thương hiệu từ Mỹ, sản xuất tại Malaysia, với chi phí cạnh tranh và thời gian giao hàng nhanh chóng. Sepro hiện là đại lý độc quyền phân phối các dòng sản phẩm của QuantumTec tại Việt Nam.

Vật tư phòng sạch:

- Vải lau phòng sạch (Polyester, CP), Tăm bông, cây lau Phòng sạch, Thảm dính bụi.

- Quần áo, găng tay Phòng sạch và Kính chống đọng sương.

Dịch vụ:

- Giặt quần áo, giày và găng tay Phòng sạch đáp ứng tiêu chuẩn ISO 14644-1, FED 209E và GMP (EU, WHO).

- Gia công: Kệ, xe đẩy, thiết bị lọc và các sản phẩm phụ trợ khác dùng trong môi trường Phòng sạch.

Sepro cam kết cung cấp giải pháp toàn diện cho môi trường Phòng sạch, đáp ứng tiêu chuẩn GMP – ISO khắt khe trong ngành Dược phẩm, y tế.

Tham khảo thêm bài viết trên FanPage

ABSORBENT MATERIALS (VẬT LIỆU THẤM HÚT) – GIẢI PHÁP TỐI ƯU CHỐNG TRÀN HÓA CHẤT