TẠI SAO IPA 70 LÀ “TRỢ THỦ ĐẮC LỰC” CHO NHÀ MÁY DƯỢC PHẨM?

1. Cồn IPA – “Vệ sĩ” diệt khuẩn hàng đầu

IPA (Isopropanol hay Isopropyl Alcohol) là một hợp chất hóa học thông thường, mà còn là “vũ khí” lợi hại trong việc chống lại vi khuẩn, virus và nấm mốc. Với khả năng bay hơi nhanh, không để lại cặn và hiệu quả diệt khuẩn vượt trội, cồn IPA là lựa chọn số một cho các quy trình vệ sinh và khử trùng trong ngành Dược phẩm.

2. Tại sao IPA được “săn đón” trong nhà máy Dược phẩm

2.1 Sát khuẩn “thần tốc”, hiệu quả vượt trội

Cồn IPA 70 ở nồng độ 70% được xem là ‘chuẩn vàng” trong khử trùng. Ở nồng độ này, IPA có khả năng tiêu diệt đến 99.99% vi khuẩn, virus và nấm mốc chỉ trong thời gian ngắn.

Đặc biệt, nồng độ 70% là nồng độ thích hợp, đảm bảo thời gian tiếp xúc đủ lâu để tiêu diệt vi khuẩn trước khi bay hơi và mang lại hiệu quả tối ưu.

2.2 Ứng dụng đa dạng, đáp ứng nhu cầu khử trùng

Vệ sinh bề mặt thiết bị, máy móc: IPA giúp loại bỏ tối đa vi khuẩn và chất gây ô nhiễm trên các thiết bị sản xuất, đảm bảo môi trường làm việc luôn sạch sẽ và an toàn.

Đáp ứng tiêu chuẩn an toàn và quy định ngành: Sử dụng IPA giúp các nhà máy Dược phẩm đáp ứng các quy định nghiêm ngặt về vệ sinh và kiểm soát nhiễm khuẩn theo tiêu chuẩn USP (United States Pharmacopeia) và GMP (Good Manufacturing Practice).

3. IPA 70 đã lọc và IPA 70 Công nghiệp – Đâu là sự khác biệt?

IPA 70 đã lọc (Pharmaceutical-grade IPA): Đây là “phiên bản cao cấp” của cồn IPA, với độ tinh khiết cao, đã qua quá trình lọc 0.2 micromet. Loại này được sử dụng trong các ứng dụng y tế, dược phẩm và sản xuất thiết bị y tế, đảm bảo an toàn và đáp ứng các tiêu chuẩn nghiêm ngặt như USP và GMP.

IPA 70 công nghiệp: Đây là loại IPA có độ tinh khiết thấp hơn và thường chứa tạp chất. Nó phù hợp cho các ngành công nghiệp như sản xuất sơn, dung môi tẩy rửa, nhưng không đáp ứng được yêu cầu khắt khe của ngành Dược phẩm.

|

IPA 70 đã lọc |

IPA 70 Công nghiệp |

|

| Quy trình sản xuất | Sản xuất trong dây chuyền Aseptic khép kín | Dây chuyền không khép kín |

| Độ tinh khiết | Cao, lọc 0.2 Micromet giúp kiểm soát vi sinh | Thấp hơn, chưa qua xử lý lọc, chứa tạp chất |

| Ứng dụng | Dược phẩm, Y tế, sản xuất thiết bị y tế | Các ngành công nghiệp như sản xuất sơn, dung môi tẩy rửa… |

| Tiêu chuẩn | USP, GMP, các tiêu chuẩn dược phẩm quốc tế | Không đáp ứng tiêu chuẩn dược phẩm USP và GMP EU |

| An toàn | Ít ảnh hưởng đến sức khỏe và môi trường | Có thể chứa VOCs gây tác động tiêu cực |

| Khả năng bay bơi | Bay hơi nhanh, không để lại tạp chất | Bay hơi chậm hơn, để lại cặn, tạp chất |

4. Nên mua IPA loại nào, ở đâu?

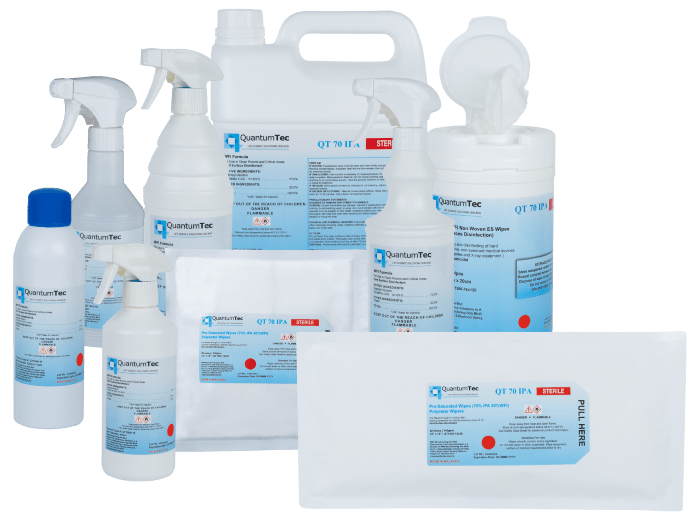

Khi chọn mua IPA 70 hãy ưu tiên các thương hiệu uy tín, được cấp phép đầy đủ để đảm bảo chất lượng và an toàn. Sepro là một trong những nhà phân phối chính thức của QuantumTEC – thương hiệu hàng đầu về hóa chất vệ sinh và khử trùng tại Việt Nam, cam kết cung cấp sản phẩm chất lượng cao với giá cả cạnh tranh.

5. QuantumTEC IPA 70 của Sepro nổi bật với các ưu điểm sau:

Hiệu quả khử khuẩn cao: Được chứng nhận tiêu diệt đến 99.99% vi khuẩn, virus.

Độ tinh khiết cao: Lọc 0.2 micromet loại bỏ các tạp chất, giúp giảm nguy cơ nhiễm bẩn chéo.

An toàn cho người sử dụng: Không gây kích ứng da, phù hợp cho cả việc khử trùng bề mặt và sát khuẩn tay.

Tiện lợi: Đóng gói đa dạng, đáp ứng mọi nhu cầu sử dụng từ cá nhân đến quy mô công nghiệp.

6. Kết Luận

Cồn IPA 70 là giải pháp khử trùng hiệu quả và không thể thiếu trong nhà máy Dược phẩm. Với khả năng diệt khuẩn mạnh mẽ, bay hơi nhanh và ứng dụng linh hoạt, IPA giúp đảm bảo môi trường sản xuất thuốc luôn vô trùng, an toàn.

Hãy liên hệ Sepro ngay hôm nay để nhận được tư vấn và hỗ trợ tốt nhất!

>>> Xem chi tiết sản phẩm Cồn IPA tại đây

Liên hệ Sepro:

Quý khách hàng có nhu cầu đặt hàng hoặc tư vấn kỹ thuật, vui lòng liên hệ:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – Giải pháp tối ưu cho môi trường phòng sạch.

#SeproEcoClean #QuantumTec #HóaChấtKhửTrùng #PhòngSạch #Giải pháp phòng sạch #Cồn IPA # IPA 70

Các sản phẩm chính:

Hóa chất khử trùng QuantumTec – Thương hiệu từ Mỹ, sản xuất tại Malaysia, với chi phí cạnh tranh và thời gian giao hàng nhanh chóng. Sepro hiện là đại lý độc quyền phân phối các dòng sản phẩm của QuantumTec tại Việt Nam.

Vật tư phòng sạch:

- Vải lau phòng sạch (Polyester, CP), Tăm bông, cây lau Phòng sạch, Thảm dính bụi.

- Quần áo, găng tay Phòng sạch và Kính chống đọng sương.

Dịch vụ:

- Giặt quần áo, giày và găng tay Phòng sạch đáp ứng tiêu chuẩn ISO 14644-1, FED 209E và GMP (EU, WHO)

- Gia công: Kệ, xe đẩy, thiết bị lọc và các sản phẩm phụ trợ khác dùng trong môi trường Phòng sạch

Sepro cam kết cung cấp giải pháp toàn diện cho môi trường Phòng sạch, đáp ứng tiêu chuẩn GMP – ISO khắt khe trong ngành Dược phẩm, y tế.

Tham khảo thêm bài viết trên FanPage

>> Xem thêm: KIỂM SOÁT VI SINH TẠI PHÒNG SẠCH