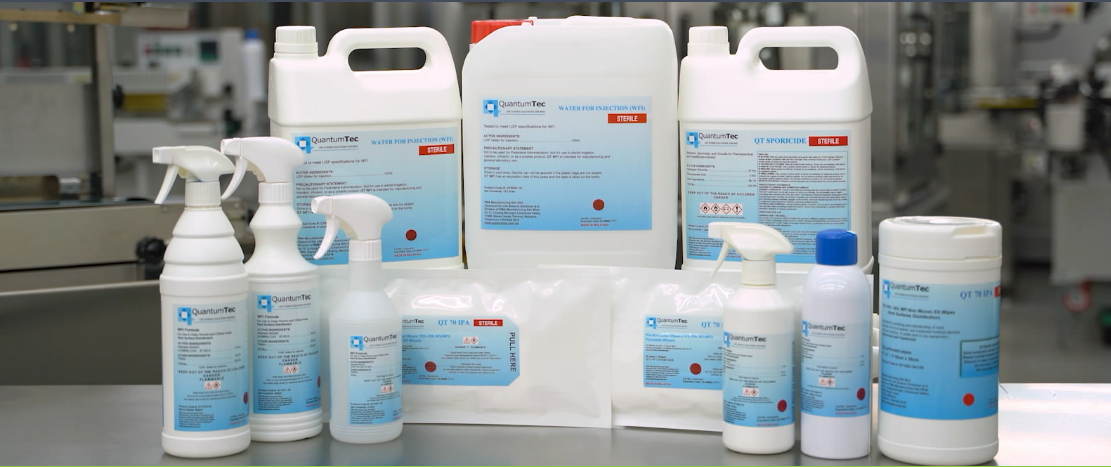

QUANTUMTEC DISINFECTANT CHEMICALS – SOLUTIONS FOR CONTROLLED ENVIRONMENTS

QuantumTec disinfectant chemicals are the ideal solution for environments requiring strict sterility such as the Pharmaceutical, Biotechnology and Medical Device Manufacturing industries.

Below is a summary of QuantumTec disinfectant chemical lines, along with practical applications and outstanding bactericidal effectiveness of each type.

1. QT Sporicide

Concept: A solution combining Peracetic Acid and Hydrogen Peroxide – a strong oxidizing agent that kills both common bacteria and spores.

Applications: Disinfection of surfaces and equipment, sterile manufacturing areas and biological research centers.

Advantages: Eliminates up to 99.999% of microorganisms, including spores, after just 10 minutes of contact.

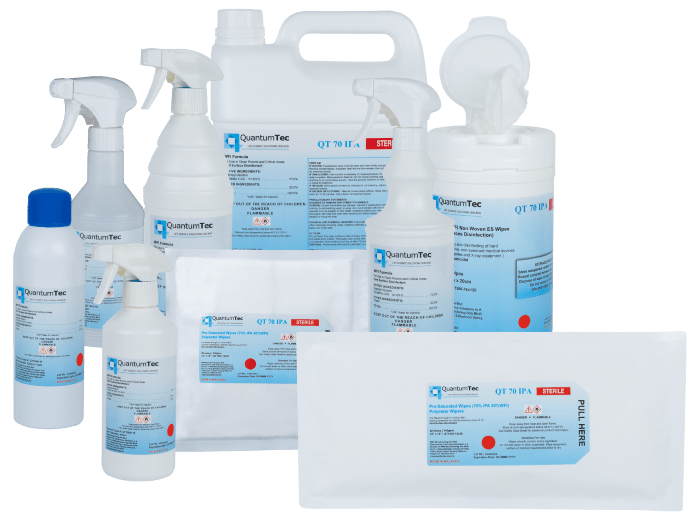

2. QT IPA 70% (Isopropyl Alcohol 70%)

Concept: Solution containing 70% Isopropyl Alcohol mixed with 30% WFI – optimal ratio for effective bactericidal effect.

Application: Used for disinfection in clean rooms, equipment, surfaces, hands, gloves, before and after operations.

Advantages: Evaporates quickly, leaves no residue, highly effective against bacteria, viruses and yeast.

3. QT Quat (Quaternary Ammonium Compounds)

Concept: Quaternary ammonium compound, capable of destroying the cell membrane of microorganisms.

Application: Suitable for sterilizing clean rooms, production lines and areas requiring control.

Advantages: Fast effect, safe for users, less irritating, easy to dilute and does not corrode materials.

4. QT Hydrogen Peroxide (H₂O₂) 3% – 6%

Concept: Hydrogen Peroxide (H2O2) is a strong oxidizing compound, exists as a colorless liquid and decomposes into water and oxygen.

Application: Surface disinfection, anti-cross-contamination, safe and environmentally friendly.

Advantages: Broad spectrum sterilization. Recognized by FDA, WHO, EPA for safety and effectiveness.

5. QT Sodium Hypochlorite (Javen) 0,52% và 5,25%

Concept: Solution containing NaOCL (Javen), is a popular disinfectant in the pharmaceutical, medical and water treatment industries.

Applications: Disinfection of equipment surfaces and work areas, water treatment and air disinfection.

Advantages: Strong antibacterial ability, highly effective and easy to use.

6. QT Detergent

Concept: Contains Alkoxylate alcohol cleaning agent, low foaming, capable of removing dirt, grease and protein before and after disinfection.

Application: Pre-treatment in cleaning process of equipment, factory surfaces, suitable for cleaning floors, walls and ceilings.

Advantages: Effective in removing residue by Sodium Hypochlorite disinfectant.

7. QT CIP : CIP 360 & CIP 361

7.1 QT CIP 360

Concept: Alkaline, non-foaming cleaner.

Application: Removes inorganic dirt, hard water deposits or minerals.

Advantages: Use in Clean-In-Place (CIP) systems, pressure washers and automatic cleaning equipment at temperatures from 50oC to 80oC. Cleans surfaces without leaving residue.

7.2 QT CIP 361

Concept: Acidic, non-foaming cleaner

Application: Removes inorganic dirt, hard water deposits or minerals.

Advantages: No foaming, no pollution, no odor.

8. QT 70 SDA: 70 SDA with IPA ; 70 SDA with Methanol

8.1 QT 70 SDA with IPA

Concept: Contains 70% concentrated Ethanol with IPA and 30% USP WFI

Application: Cleaning surfaces, equipment, gloves in sterile areas and used in controlled environments.

Advantages: Evaporates quickly, safer, mild, pleasant odor, leaves no residue and high bactericidal efficiency.

8.2 QT 70 SDA with Methanol

Concept: Contains 70% Ethanol Concentrate with Methanol and 30% USP WFI

Application: Cleaning surfaces, equipment, gloves in sterile areas and use in controlled environments.

Advantages: Evaporates quickly, has a stronger and more pungent odor than IPA, leaves no residue and is highly effective in killing bacteria.

9. QT WFI

Concept: Pure water through 2 processes of reverse osmosis filtration and final 0.1µm filtration, free of bacteria and impurities.

Application: Dilute disinfectant chemicals, final rinse in cleaning process.

Advantages: Meets the United States Pharmacopeia (USP) Water for Injection standards.

10. WHY CHOOSE QUANTUMTEC DISINFECTANT CHEMICALS?

- There are 2 product lines, Sterile and Non-Sterile, suitable for a variety of usage needs.

- Filtered at 0.2µm, ensuring the removal of microorganisms from the input.

- Manufactured in a sterile environment (Aseptic Manufacturing), according to USP standards.

- The Sterile line is irradiated with Gamma according to ISO 11137 standards, ensuring the level of sterility (SAL 10⁻⁶).

- Chemicals are packaged safely, traceable, suitable for GMP, WHO, EU-GMP, FDA systems.

- Genuine products, full COA – MSDS.

Contact Sepro:

If you need to order or have technical advice, please contact:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – The optimal solution for clean room environments.

#SeproEcoClean #QuantumTec #Disinfectant Chemicals #Clean Room #Clean Room Solutions #H2O2 3% #Peroxy Pure #Hydrogen Peroxide

Main products:

QuantumTec disinfectant chemicals – Brand from the US, manufactured in Malaysia, with competitive costs and fast delivery time. Sepro is currently the exclusive distributor of QuantumTec products in Vietnam.

Cleanroom supplies:

- Cleanroom Wipers (Polyester, CP), Cleanroom swabs, Mopping System, Sticky Mats.

- Cleanroom coverall, gloves and Anti-fog glasses.

Services:

- Washing of cleanroom wipers, shoes and gloves meeting ISO 14644-1, FED 209E and GMP (EU, WHO) standards

- Processing: Shelves, trolleys, filters and other auxiliary products used in cleanroom environments

Sepro is committed to providing comprehensive solutions for Cleanroom environments, meeting strict GMP – ISO standards in the pharmaceutical and medical industries.

See more articles on the FanPage

QUANTUMTEC IPA 70 – EFFECTIVE DISINFECTION SOLUTION