CLEANROOM WIPER: THE ULTIMATE CLEANING SOLUTION FOR CONTROLLED ENVIRONMENTS

In modern industries, maintaining a clean and safe environment is extremely important.

Cleanroom wiper are not only a common cleaning item but also an effective solution to prevent cross-contamination and protect product quality.

Cleanroom wiper play an essential role in maintaining cleanroom hygiene for fields such as electronics, pharmaceutical, and medical device manufacturing.

This article will introduce cleanroom wipes, their benefits, and how to choose the most suitable type of wipes.

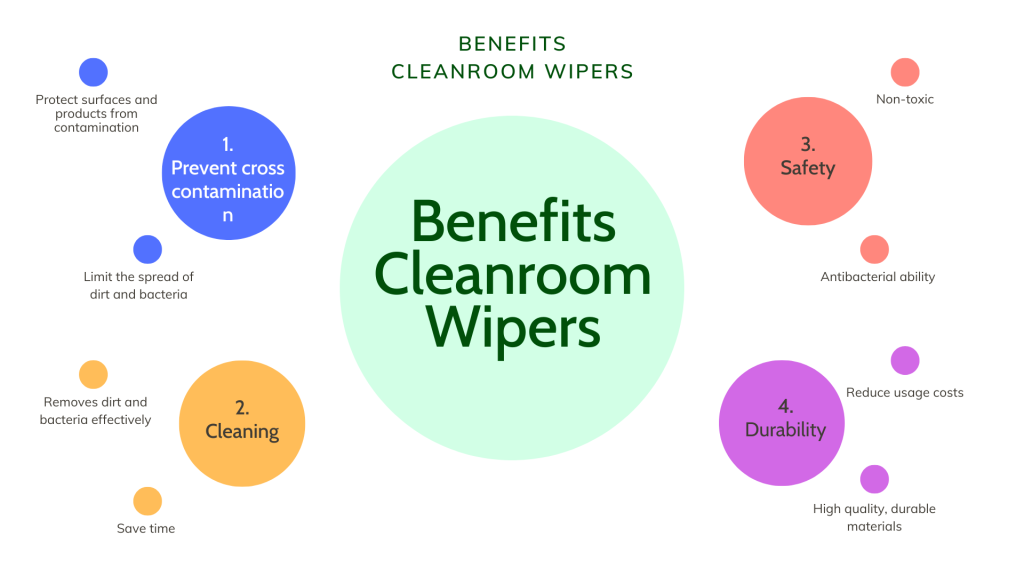

Benefits of cleanroom wiper

1. Prevent cross contamination

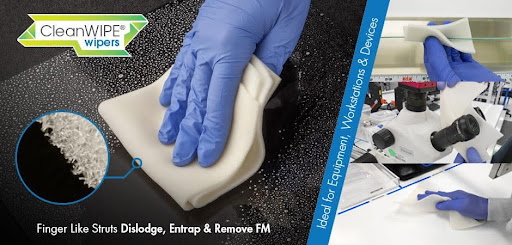

Cleanroom wiper are specially designed to limit the spread of dirt and bacteria. They are typically made from lint-free materials and free of harmful chemicals, helping to protect surfaces and products from contamination.

2. Enhanced cleaning performance

With good absorbency, cleanroom wiper help remove dirt and bacteria more effectively than regular towels. This not only saves time but also improves cleanroom cleaning efficiency.

3. Safe For Users

Cleanroom wiper are usually free of toxic chemicals, helping to protect the health of users. This is especially important in working environments such as hospitals, laboratories and manufacturing plants.

4. High Durability

Cleanroom wiper are often made from high-quality materials that are tear-resistant and durable during use. This helps reduce costs for businesses in replacing wipes frequently.

Types of wipes commonly used in clean rooms

Below are common types of wipes used in cleanrooms:

1.Polyester wiper:

- Features: Made of 100% polyester with tight weave, no shedding and high durability.

- Advantages: Anti-static, chemical resistant, no dust particles. This type of towel is often laser cut to avoid shedding at the edges.

- Application: Used in environments requiring high cleanliness such as semiconductor manufacturing, pharmaceuticals and medical equipment.

2. Microfiber wiper:

- Features: Made of microfibers with high absorbency and ultra-fine dust removal. Microfiber towels are usually very soft and light.

- Advantages: Good dust holding capacity without scratching the surface, suitable for wiping sensitive surfaces.

- Applications: Widely used in clean rooms for manufacturing electronic components, screens, optics, and equipment requiring high hygiene.

3. Poly-Cellulose Wiper:

- Features: A blend of polyester and cellulose, giving the towel the strength of polyester and the absorbency of cellulose.

- Advantages: Absorbs better than pure polyester and does not shed fibers. Suitable for wiping surfaces or absorbing liquids.

- Applications: Widely used in clean rooms for pharmaceutical, food, and laboratory production.

4. Nonwoven Wiper:

- Characteristics: Non-woven towels, usually made from polyester, polypropylene or cellulose fibers. These towels are made by compressing fibers instead of weaving.

- Advantages: Low cost, good absorbency, no fiber shedding, easy to use and discard after use.

- Applications: Suitable for clean rooms with low or medium cleanliness requirements, used in jobs that require disposable wipes.

5. ESD Wiper:

- Features: ESD towels are made from polyester fibers mixed with antistatic agents to control static electricity.

- Advantages: Prevents static electricity buildup, does not pose a risk to sensitive electronic devices.

- Applications: Suitable for electronic and semiconductor manufacturing environments, and areas requiring static control.

6. Foam Wiper:

- Features: Made from sponge or similar synthetic material, with excellent liquid absorption.

- Advantages: Fast and effective absorption, easy to clean solutions or chemicals.

- Applications: Used to clean solutions and chemicals in clean rooms, especially when fast absorption is required.

7. Sterile wiper:

- Features: Sterilized wipes, do not contain bacteria or other microorganisms. They are usually packaged in a sterile environment.

- Advantages: Ensures microbiological safety, does not cause any biological contamination.

- Applications: Used in cleanroom environments that require high sterility, such as in medical, pharmaceutical manufacturing, and biological laboratories.

Types of cleaning cloths used according to clean room level

Below are the cleanroom levels according to ISO 14644-1 and their relevance to the type of wiper :

1. Clean room ISO Class 1 – 3

- Suitable wipes: 100% laser cut polyester wipes, microfiber wipes, nonwoven wipes and sterilized wipes with extremely fine fiber structure to capture and remove microscopic dust particles without causing contamination.

2. Cleanroom ISO Class 4 – 6 (Level 4 to Level 6)

- Suitable Wipes: Polyester wipes, microfiber wipes, poly-cellulose wipes and anti-static wipes (ESD wipes) are commonly used in environments where dust contamination control and prevention is required.

3. ISO Class 7 – 8 Clean Room (Class 7 to Class 8)

- Suitable Wiper: Nonwoven, microfiber, polyester and poly-cellulose cleaning cloths are good choices for cleaning surfaces without generating large dust particles.

4. ISO Class 9 Clean Room

- Suitable Wipes: Poly-cellulose wipes, or microfiber wipes are used for environments that require general cleaning, such as in food packaging or dental clinics.

Conclude

Cleanroom wipes and regular wipes have distinct differences in material, absorbency, safety and durability. For environments that require strict hygiene, such as hospitals or laboratories, cleanroom wipes are the best choice. Meanwhile, regular wipes may be suitable for simpler cleaning tasks.

Consider carefully when choosing the right wipe for your needs to ensure hygiene and efficiency in work!

Contact Sepro:

If you need to order or have technical advice, please contact:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – The optimal solution for clean room environments.

#SeproEcoClean #QuantumTec #Disinfectant Chemicals #Clean Room #Clean Room Solutions #H2O2 3% #Peroxy Pure #Hydrogen Peroxide

Main products:

QuantumTec disinfectant chemicals – Brand from the US, manufactured in Malaysia, with competitive costs and fast delivery time. Sepro is currently the exclusive distributor of QuantumTec products in Vietnam.

Cleanroom supplies:

- Cleanroom Wipers (Polyester, CP), Cleanroom swabs, Mopping System, Sticky Mats.

- Cleanroom coverall, gloves and Anti-fog glasses.

Services:

- Washing of cleanroom wipers, shoes and gloves meeting ISO 14644-1, FED 209E and GMP (EU, WHO) standards

- Processing: Shelves, trolleys, filters and other auxiliary products used in cleanroom environments

Sepro is committed to providing comprehensive solutions for Cleanroom environments, meeting strict GMP – ISO standards in the pharmaceutical and medical industries.

See more articles on the FanPage