CLEANROOM COVERALL – AN EFFECTIVE PROTECTION SOLUTION FOR CLEANROOM ENVIRONMENTS

Cleanroom coveralls are essential protective clothing in industries that require high cleanroom standards, such as electronics manufacturing, pharmaceuticals, biotechnology, and semiconductors. Let’s explore why cleanroom coveralls are necessary, their functions, and the common types available today.

1. Why Cleanroom Coverall are necessary

- Dust and Microorganism Control: Prevent dust generation and block dust and bacteria from human sources.

- Static Electricity: Reduce static buildup, protecting sensitive components.

- Cleanliness: Ensure cleanliness and are sterilized before use.

2. Functions of Cleanroom Coverall

- Dust and Microorganism Control: Block dust and bacteria from the body, maintaining a cleanroom environment.

- Product Protection: Ensure quality in electronics, pharmaceuticals, and biotech industries.

- Static Control: Prevent static buildup, protecting sensitive components.

- Compliance with Hygiene Regulations: Meet FDA, ISO hygiene and safety standards.

3. Types of Cleanroom Coverall

Here is a comparison table between two popular types of cleanroom coveralls: Disposable Coveralls and Reusable Coveralls.

| Disposable coverall |

Reusable coverall |

|

| Material | Nonwoven Polypropylene, Microporous Fabric | Polyester, combined with carbon fibers |

| Fabric Characteristics | Loose structure, lightweight, breathable | Thick, smooth structure, excellent fiber and particle control |

| Static Control | Low static control, mainly due to the fabric structure | High static control due to the interwoven carbon fibers |

| Durability | Single-use, prone to fiber shedding and dust, not durable | Reusable multiple times, durable, and resistant to sterilization |

| Application | Low-level cleanrooms (ISO 7–9) | High-level cleanrooms (ISO 1–5) |

| Advantages | Cost-effective, suitable for short-term applications | Good dust and microorganism control, reusable |

| Disadvantages | Poor durability, prone to fiber shedding, not suitable for high-level cleanrooms | Higher cost, requires washing and sterilization |

4. Sepro – Providing High-Quality, Cost-Effective Cleanroom Coveralls

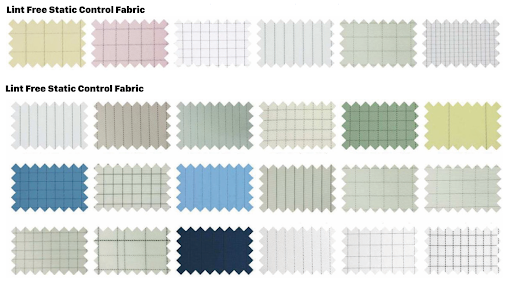

Sepro offers fabrics with high particle protection, comfort, and antistatic properties using carbon material and weaving techniques. Some common fabric uses include:

Sepro offers a wide range of cleanroom clothing, including gowns, coveralls, jackets, and t-shirts…

Sepro’s garment factory is ready to meet customers’ cleanroom garment needs with many designs, meeting strict cleanroom standards.

5. Sepro Cleanroom Shoes

Sepro Cleanroom Shoes Meet Important Standards:

- First: Static resistance ranging from 106 Ω to 109 Ω.

- Second: Slip resistance.

- Third: High durability, no fiber shedding or dust generation.

- Fourth: Shoe sizes range from size 36 to 46.

- Fifth: Made from canvas, PVC, PU, mesh, and antistatic cloth.

Common Types of Cleanroom Shoes:

- Mesh-front cleanroom shoes.

- Toe-capped cleanroom shoes.

- Four-hole cleanroom shoes.

- Cleanroom boots.

Conclusion:

Using Cleanroom Coveralls and Cleanroom Shoes helps maintain a clean working environment and enhances product safety and employee health. Sepro is committed to providing optimal cleanroom protection solutions for all your production needs.

Contact for Cleanroom Products:

If you’re looking for Cleanroom Coveralls or Cleanroom Shoes or need advice on the best products for your work environment, feel free to contact us. We specialize in providing cleanroom consumables that meet industry standards, suitable for various sectors like healthcare, pharmaceuticals, electronics, and more.

Contact Sepro:

If you need to order or have technical advice, please contact:

📞Hotline: (84) 96 825 5675

📧Email: fin@sepro.vn

🌐Website: https://sepro.vn

SEPRO ECO CLEAN – The optimal solution for clean room environments.

#SeproEcoClean #QuantumTec #Disinfectant Chemicals #Clean Room #Clean Room Solutions #Cleanroom Coverall

Main products:

QuantumTec disinfectant chemicals – Brand from the US, manufactured in Malaysia, with competitive costs and fast delivery time. Sepro is currently the exclusive distributor of QuantumTec products in Vietnam.

Cleanroom supplies:

- Cleanroom Wipers (Polyester, CP), Cleanroom swabs, Mopping System, Sticky Mats.

- Cleanroom coverall, gloves and Anti-fog glasses.

Services:

- Washing of cleanroom wipers, shoes and gloves meeting ISO 14644-1, FED 209E and GMP (EU, WHO) standards

- Processing: Shelves, trolleys, filters and other auxiliary products used in cleanroom environments

Sepro is committed to providing comprehensive solutions for Cleanroom environments, meeting strict GMP – ISO standards in the pharmaceutical and medical industries.

See more articles on the FanPage